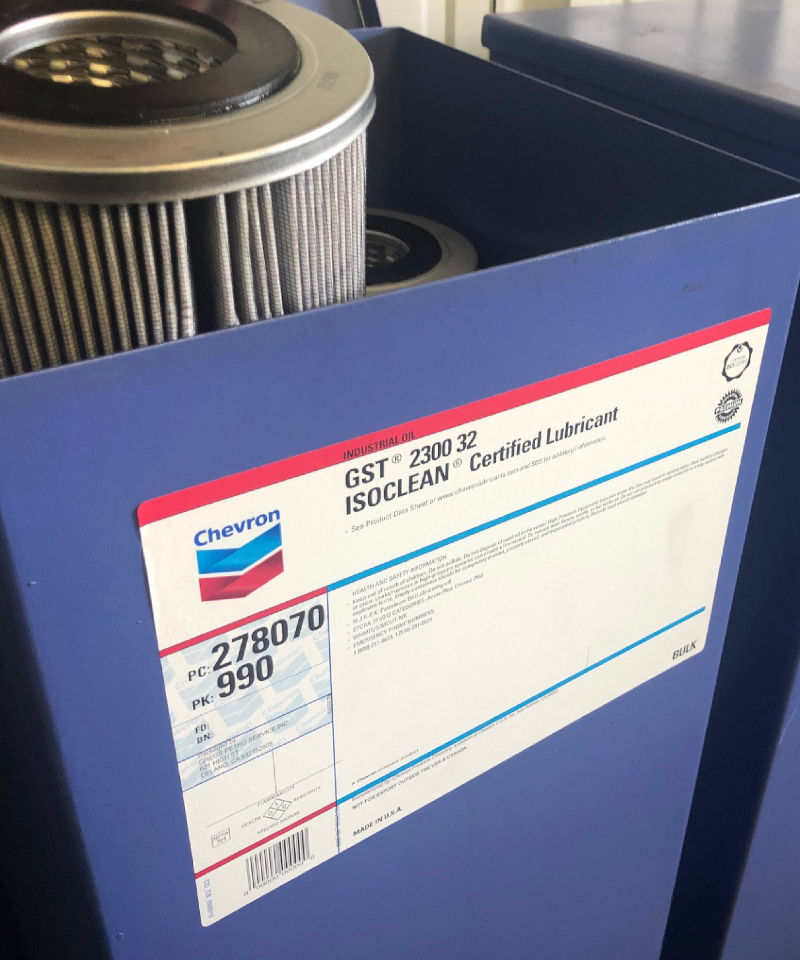

ISOCLEAN Lubricants

Start clean, stay clean

From truck fleets to power plants, any operation that depends on the reliable performance of heavy-duty equipment has to be concerned about lubricant cleanliness. Why? Simply because lube oil contamination is a primary reason for engine wear leading to diminished fuel efficiency, shorter useful oil service life, reduced component life and loss of performance.

There’s a misconception among diesel engine operators that all it takes to mitigate the risk of oil contamination is an infusion of fresh oil into the engine – that if the oil is “new” from the manufacturer, it must be “clean.” Nothing could be further from the truth.

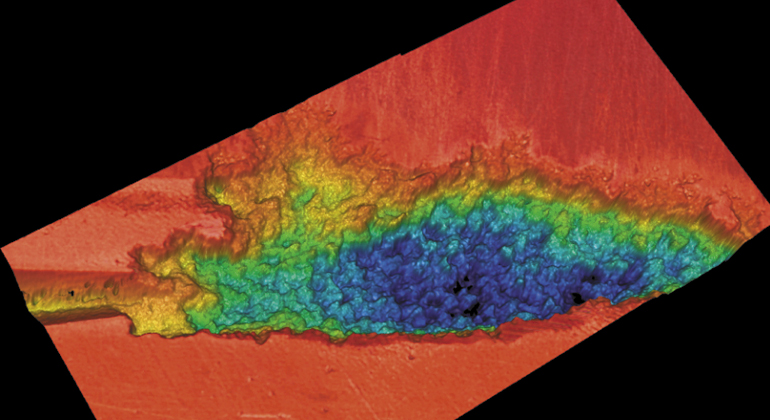

Oil is transferred as much as eight times prior to reaching your equipment. At each of those transfer points, it is exposed to particulate contamination from the environment. While these particulate contaminants may be small in size – smaller than a grain of pollen – they can wreak havoc on the performance and uptime of the equipment you depend on most. To make matters worse, component wear caused by contamination actually produces more contamination, known as the “chain reaction of wear.” Left unchecked, this chain reaction can lead to increased friction, shortened service intervals, loss of compression, increased fuel consumption and reduced component life.

Typical oil vs Clean oil: Does it matter?

Short answer, yes it does. Watch our Proof of Performance video series to see why starting with certified clean Chevron ISOCLEAN® Lubricants can help you avoid costly equipment downtime, unplanned service costs and unexpected repairs.