As a fuel and lubricant supplier, we work with many different industries. Our team helps to keep farmers working in their fields, semi-trucks delivering loads, construction equipment working, and even industrial machinery moving. Our products are widely used in various industries with specific fuel and lubricant needs.

In this blog, we want to discuss a specific need many industrial customers face, bearing failures. For many of our industrial customers who run large-scale machinery in plants, a bearing failure is a big deal. It can mean the shutdown of large machinery they need to produce their products or work. So let’s talk about bearing failures and how we can help prevent them.

What are bearings?

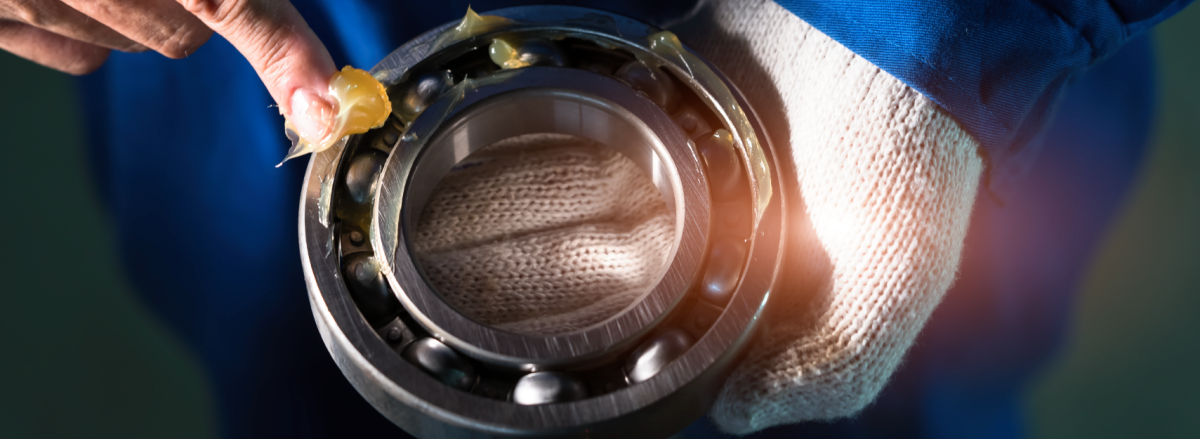

If you skipped engineering class on the day they taught about bearings, that’s okay. Let us explain. There are many different types of bearings, but basically, a bearing is a rotating shaft used to reduce friction between moving parts. In machinery, bearings transmit a load and minimize friction, like a crankshaft in an engine or a lathe spindle. There are many different types of bearings that are used in various applications. To learn more about each type of bearing, watch this video!

Bearings are a vital part of many industrial machines. They work great and keep the machinery running. But when there is a bearing breakdown, it can be costly and time-consuming because it may necessitate taking large pieces of machinery apart or getting into a small or tight area to fix the bearing.

What causes bearing failures?

A bearing can fail in many ways, but the primary reason is usually a lubricant failure. Lubricating bearings is essential for keeping them in good working order. So when the lubricant isn’t working correctly, the bearing will start to break down. So what kind of lubricant issues are most common?

- Not using enough lubricant

- Using a lubricant with the wrong viscosity

- Lubrication deterioration

- Going too long before adding more lubricant

- High temperatures

- Using a grease lubricant instead of a static or circulating oil

- Using the wrong grease

- Over lubrication

- Particle contamination.

Particle Contamination is the primary reason for bearing failure.

Let’s focus on particle contamination because it’s the most common reason a bearing failure occurs. When a contaminated lubricant is used on a bearing, it can cause a failure because the particles in the lubricant increase the friction between the moving parts, gum up the motion, or damage the bearing. Over time this effect will wear down the bearing and cause damage. It’s why using clean lubricants is so essential.

To prevent bearing failures from particle contamination, the International Organization for Standardization has created ISO 281 as a standard for determining bearing life. This standard is used not to determine lubricant cleanliness but instead the maximum level of particle contamination the bearing can take before it is negatively affected. This standard allows plant owners and machine operators to determine the basic rating life in conventional operating conditions and with proper lubrication.

How can you prevent lubricant failures?

The ISO 281 standard is a great way to stay on top of your bearing life. If your bearings surpass that standard, then you know it’s time to replace or repair the bearing. But what can you do to keep your bearings operating at this standard? Follow these three best lubricant practices.

- Use the right amount of lubricant: Make sure you know precisely how much lubricant you need to use on your bearings. Too much or too little can negatively affect bearing performance.

- Use the correct type of lubricant: Make sure you use the recommended lubricant for your bearings based on the bearing, how it’s used, and the conditions the bearing is operated in.

Clean lubricant is the best!

The best lubrication practice to protect the life of your bearings is to focus on lubricant cleanliness. Particle contamination will occur. Even fresh out-of-the-box products have some level of contamination, so it’s up to you to minimize the contamination levels in your lubricant products. There are a few different ways you can do this, including:

- Practice proper lubricant storage and handling practices. To reduce contamination of your lubricant products, you’ve got to store and handle them properly. Remember, follow the 5S’s of storage: Sort, Straighten, Shine, Standardize, and Sustain. For a good refresher on these practices, read our previous blog!

- Utilize on-site filtration to remove any potential contaminants. Filtering your lubricant products before putting them on your bearings is a standard practice for many businesses. Just make sure you are following proper filtration procedures to ensure cleanliness.

- Get your oils and lubricants tested. Another excellent method is testing your lubricants as part of our oil analysis program. Using samples from your supplies, which our lab partner then analyzes, you’ll get hard data on your lubricant cleanliness and effectiveness. It’s a great way to ensure that your supplies are clean and working correctly.

- Use Chevron ISOCLEAN lubricants. If you don’t have the time or resources to filter or test your lubricant supplies, try using Chevron ISOCLEAN lubricants. ISOCLEAN lubricants are tested and produced to meet OEM cleanliness requirements and increase component and equipment life. They are cleaner out of the box and contain few particles than similar products. You can learn more about the ISOCLEAN standard here.

Keeping your equipment and machinery bearings in good working order is no small task. It requires diligent effort to follow best lubricant practices, including using the right lubricant supplies and ensuring they are clean enough for your equipment. Switching to Chevron ISOCLEAN lubricants is another excellent way to keep your bearings in good working order. These products are cleaner and work better, so they will provide the protection your bearings need. Talk to your Greg’s Petroleum representative today about using ISOCLEAN lubricants in your machinery!